In part 3 of our blog series “Why Mechanical Engineering is Crucial to Data Centers”, we’ll take a look at the various types of calculations, code considerations, and other daily happenings in the life of a Mechanical Engineer.

Find Parts 1 and 2 here:

Codes

There are numerous codes and standards that apply to data center design. Local building codes are always the starting point, and here in Ohio, these are based on the International Code Council (ICC) standards. It’s important to consult the Authority Having Jurisdiction (AHJ) for any local amendments or updates to these codes.

A few commonly referenced mechanical codes include ASHRAE 90.1 for energy standards, ASHRAE 62.1 for ventilation requirements, and ASHRAE TC 9.9, which covers thermal guidelines for data centers. For fire protection, key standards include NFPA 13 (sprinkler systems), NFPA 75 (protection of IT equipment), and NFPA 855 (energy storage systems).

Remember, codes establish the minimum requirements. It’s essential to discuss with clients whether there are aspects of the project where exceeding these minimums would add value or address specific needs. As mentioned in part 2, these decisions can also impact project costs.

Calculations

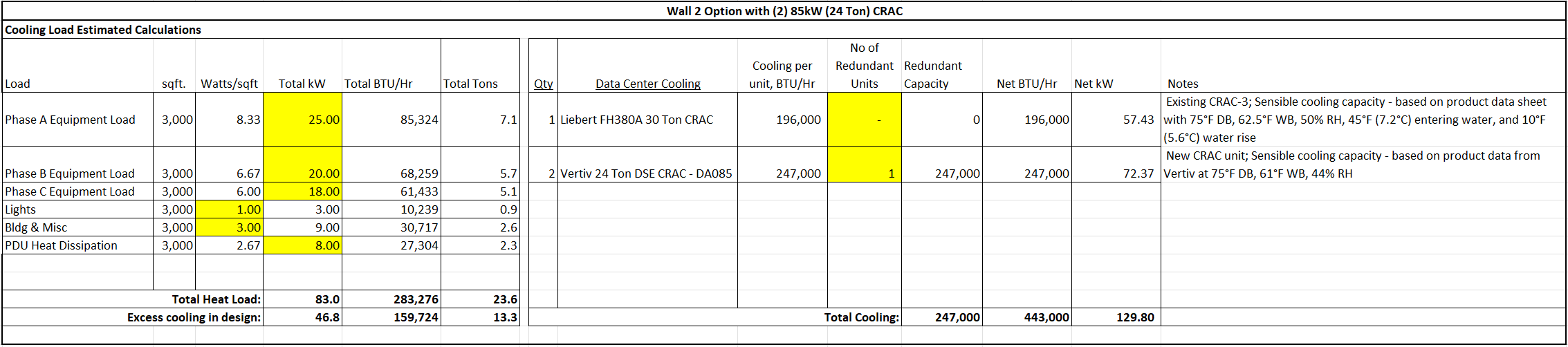

In data center design, cooling load calculations are paramount for properly sizing mechanical equipment. Rather than focusing on heating, our attention is directed toward determining the cooling requirements, which are largely influenced by the power requirements. This information guides decisions on how best to deliver cooling—whether through chilled water or air and when to implement strategies like aisle containment to optimize efficiency based on watts per rack.

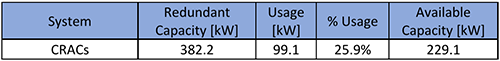

Redundancy calculations are also critical, ensuring that the cooling system can maintain 100% capacity even during equipment failures or maintenance periods. For chilled water systems, it’s essential to accurately size pumps and piping to meet the cooling demands.

Beyond the main data hall, mechanical engineers must also consider auxiliary spaces such as bathrooms, offices, and kitchenettes. These areas require calculations for airflow, hot and cold water piping, and sanitary piping to ensure comfort and compliance with building codes.

The table estimates heat loads in a space from sources like electrical equipment, lights, PDUs, and building infiltration. The right side shows each unit’s available cooling capacity; for data centers, focus on sensible cooling. Redundant equipment can be included to balance the total load.

The table shows current data center usage and potential future capacity.

A Day in the Life of a Mechanical Engineer

The best part of being an ME is that no two days are ever the same. On any given day, we might conduct site visits, meet with clients, draft designs, review drawings for quality control (QC), participate in commissioning activities, perform punch walks, or carry out complex calculations. Each site presents its own unique challenges—there are no copy-and-paste solutions in this field. While the core engineering principles remain consistent, every project requires a tailored approach. To stay effective, ME’s must continually update their knowledge of the latest industry standards, evolving codes, and energy regulations. This commitment to lifelong learning ensures that ME’s can deliver innovative and reliable solutions for every client.

Closing

We hope you found part 3 of our mechanical engineering series useful. Stay tuned for the final part of our series, “Why Mechanical Engineering is Crucial to Data Centers”, where we will discuss energy efficiency, including airflow management and containment.

If there is a topic you would like to see us cover, please let us know!