Project: Glycol Remediation

Location: Indiana

Business Sector: Utility

Services: Construction/Facility Management

Budget: $300,000

Completed: November 2023

TechSite Facility Management:

TechSite’s facility management team provides on-site support of customers’ mission-critical systems. As part of this program, scheduled checks on critical equipment are performed to ensure all systems are operating as intended.

Project Challenge:

Concerned with the condition of the glycol at two of the customer’s data centers, TechSite took samples and had a detailed analysis run by multiple labs. The laboratory tests confirmed that the glycol was degraded. The pH and corrosion inhibitor levels were out of range and there were contaminants present in the system. Rather than treat the glycol, which was not guaranteed to be successful, it was decided that a full replacement would be the better option.

Tests confirmed the glycol was degraded, and should be treated or replaced.

TechSite Solution:

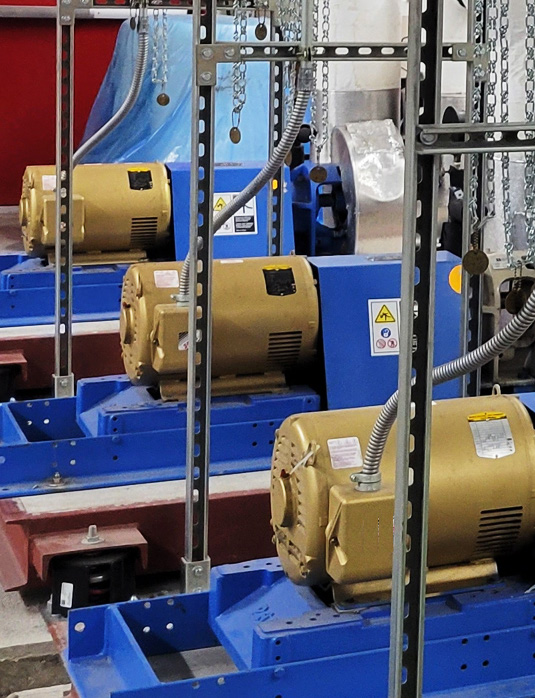

Given the critical nature of both buildings, the TechSite team created detailed Method of Procedure (MOP) plans to ensure the smooth execution of the event. Since it was necessary to shut down the cooling systems for the glycol replacement, the events were strategically scheduled during colder seasons, leveraging outside air to maintain data center temperatures. Additionally, TechSite implemented temporary cooling systems for essential equipment in electrical rooms.

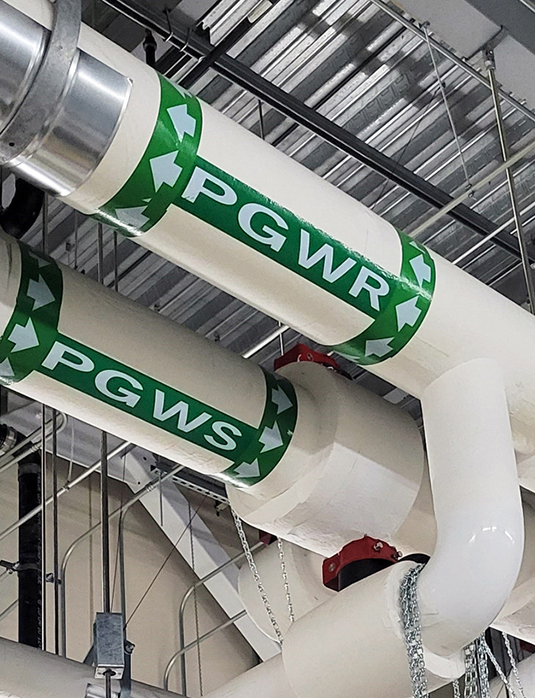

Once these measures were in place, the cooling loops were deactivated and a pumping truck was used to drain the existing glycol. Following this, a cleaning solution was pumped through the system for 24 hours and then the system was thoroughly flushed with city water. Prior to this procedure, bypass loops were installed to safeguard fan coil units and chillers from the cleaning solution and water. Upon completion of the flushing and cleaning, the bypass loops were removed and new 40% propylene glycol was pumped into the system.

Once the glycol loops were re-filled with the new fluid, the cooling systems were reactivated, commissioned, and a comprehensive final closeout report was furnished to the customer.

Concerned that your glycol may no longer be suitable for use? Contact TechSite for help maintaining this critical element of your facilities cooling system.