Preventive Maintenace (PM) work is one of the most important activities a mission-critical facility operator plans for. PM work is crucial for both the electrical and mechanical systems in a critical environment for multiple reasons:

- Confirm equipment is operating within manufacturer specifications

- Reduce the chances of unplanned downtime due to a failure

- Help maximize the equipment lifespan

- Ensure the equipment is operating safely

- Cost savings from improved efficiency of the equipment

- Cost savings from identifying and fixing issues early

Research completed by IEEE demonstrates that electrical equipment maintained at intervals greater than 24 months is 5 times more likely to fail when compared to equipment maintained within the last 12 months. Additionally, equipment serviced within the last 12-24 months still has a 50% greater chance of failure than those maintained within the last 12 months. Given these findings, TechSite recommends implementing a proactive preventive maintenance program for all the critical systems in your facilities. It is crucial to note that the quality of service has a significant impact on equipment failure rates; poorly executed service can be even more harmful than no service at all. With two decades of expertise in Maintenance Management, TechSite is well-equipped to assist customers in selecting top-notch vendors, comprehensive report analyses, addressing action items, and guaranteeing the delivery of high-quality service.

TechSite Maintenance Team

TechSite’s Maintenance Department are experts in creating preventive maintenance programs for our customers. The team offers maintenance coordination, supervision, alarm monitoring, 1st responder services, report review, and documentation. The team is comprised of highly skilled maintenance supervisors, engineers, and management staff who have an understanding of protecting critical loads and risk mitigation. The team is highly skilled in understanding, developing, and implementing Methods of Procedure (MOPs) for the maintenance activities. The team is also experienced in operating within customer’s Change Control systems and documentation environments, and following all established protocols.

Recommended PMs On Critical Systems

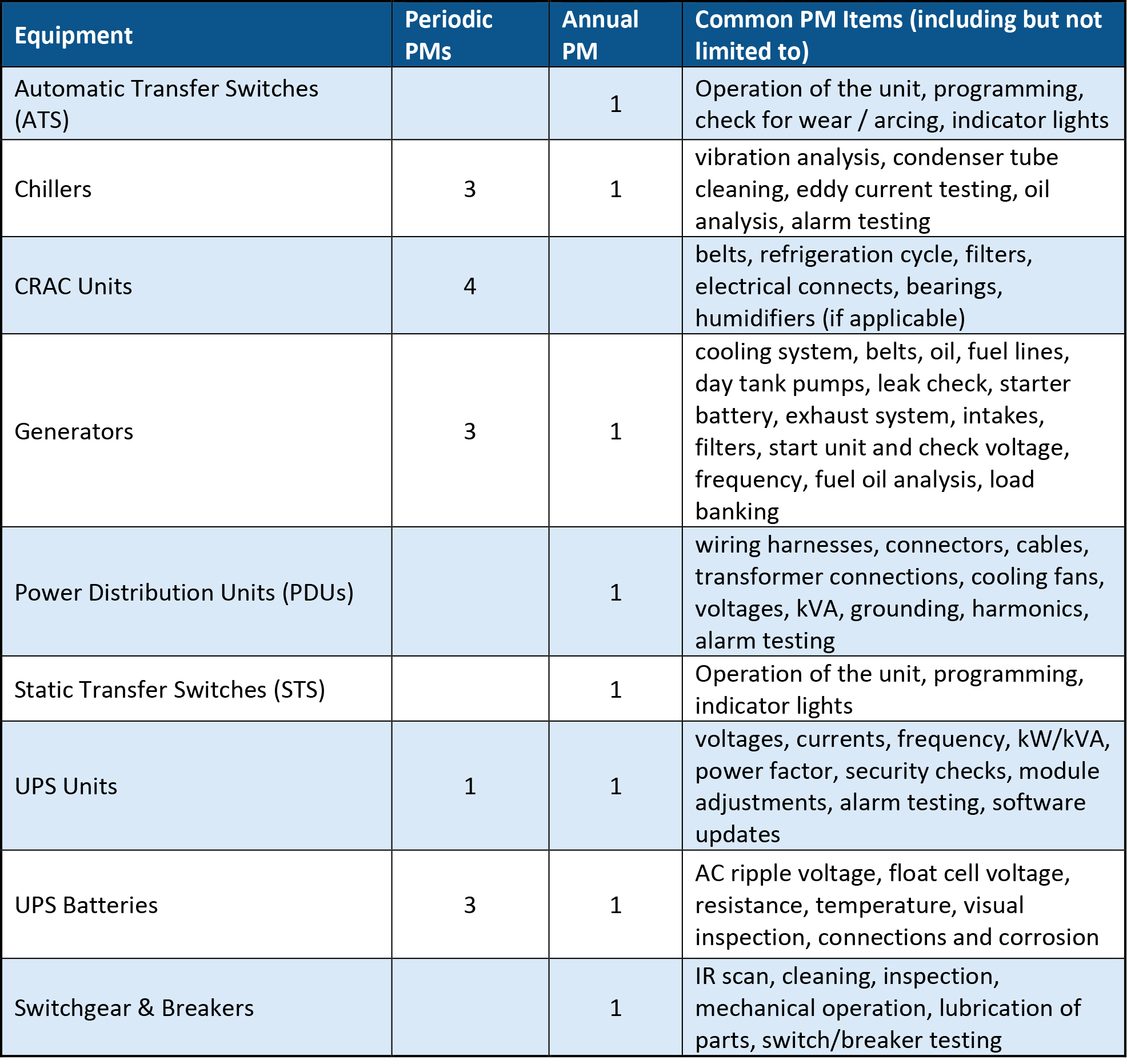

TechSite’s maintenance team plans and coordinates all the PM work to be completed annually, including periodic and annual PM events. Planning for these events is initiated at the beginning of the year, ensuring key dates are set and vendors are coordinated early to prevent any deferrals or missed PMs. Periodic maintenance, typically shorter and done more frequently, can often be done without shutting down the equipment. In contrast, annual PMs are longer events with an increase in scope and may require equipment to be de-energized. The scheduling of this work, including the optimal days, hours, or night and weekend work if required, is coordinated with both vendor and customer, factoring in all necessary constraints to ensure proper execution of all maintenance tasks.

Some of the most important PMs that TechSite’s maintenance team recommends and manages are:

Additional PM Systems

In addition to the systems noted above, the following is a sample list of additional critical systems that TechSite recommends having a PM plan:

- Air Handlers

- Backflow Preventors

- Building Management Systems (BMS)

- Cooling Towers

- Fan Coil Units

- Fire Alarm and Suppression Systems (Wet Pipe, PreAction, Clean Agent)

- Grounding Systems

- Lighting Systems

- Pumps and Motors

- Roof Top Units (RTUs)

- Variable Air Volume Units (VAVs)

- Variable Frequency Drives (VFDs)

- Very Early Smoke Detection Systems (VESDAs)

- Water Purification Systems

- Water Treatment Systems

Deliverables

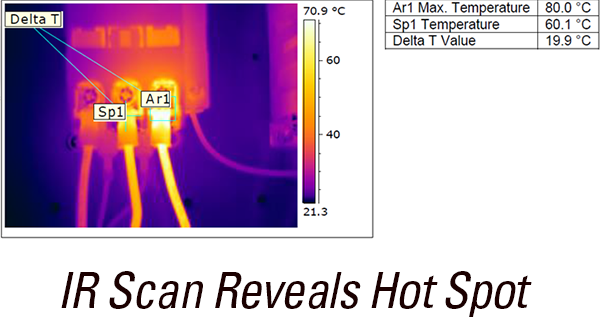

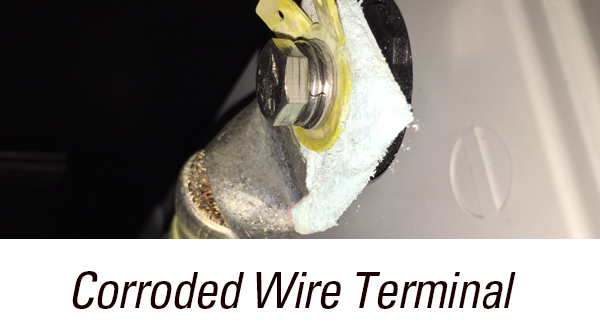

In alignment with our commitment to ensuring a quality PM is completed, TechSite provides a comprehensive report to the customer upon completion of the PM. The report details the work performed, any issues that were found, problems that were resolved during the PM, and recommendations for future maintenance and repair of the equipment. These may include reports on generator fuel condition, quality of the glycol in a chiller loop, UPS battery life remaining, IR scanning hot spots, motor vibration anomalies, and more. Additionally, TechSite evaluates system capacity, using historical trending and current load reports, to provide a thorough assessment of equipment utilization. This assessment is used for evidence-based future-planning to ensure our customers are well informed on all aspects of their critical systems.

Closing

TechSite knows how important mission critical systems are to our customers’ ability to conduct their business. Recognizing the importance of maintaining continuous operation, we are adept at planning and managing preventive maintenance work during off-peak hours, such as nights and weekends, to mitigate any risks during regular business hours. With two decades of experience working in critical environments, our team can expertly coordinate all PM activities, taking into account critical scheduling requirements like customers’ blackout dates and vendor availability. TechSite’s Maintenance Team has the experience and ability to deliver the most effective PM program for mission-critical facilities, tailored to meet your objectives and ensure uninterrupted business continuity.